Made some progress on rebuilding the binnacle this weekend

Of course I still need to rebuild the actu helm pump but the pieces are not in yet also need to add the valves but same story

The Refit of a 1976 Whitby 42 Ketch – Akupara

Brought the freshly painted binnacle home on the weekend and starting to reinstall all of the new pieces. I guess that isn’t reinstalling but I think you get my point.

Of course I have completely forgotten how to run the tubing for the hydraulic steering so I have reached out to the owners group for help.

I can’t remember how long it has been since I added anything to this blog.

I can’t remember the last time I actually did any work on Akupara.

I can’t remember why we even started this project, only to get so close and then to let it all slip away.

I think Covid has a lot to do with it. The complacency, the desire to just hide. Who knows.

If we don’t make an honest stab at it now, it will forever be lost…

I watched a video of a guy with his Whitby 42 this morning.

I miss sailing. I miss the aloneness. I miss the shrinking of one’s universe to the point that it starts at the bow and ends at the stern.

I need to sail.

Enough said.

Well we got the official word today, time to permanently reinstall Akupara’s deck fittings from the cockpit forward!!!!!

Once done, they will spray the nonskid on that area.

Pretty excited!!!!

This project has taken way longer than either of us had planned. To be honest there have been long stretches where we completely gave up and there have been many moments, especially in the last year, where I considered throwing in the towel completely and just walking away.

We actually started going camping just to get outdoors. To be away from the city and the crowds especially with Covid 19.

And then Prodigy Marine sends me a picture of the decks nearing completion and our hearts begin to race and our excitement returns full force.

We remember why we started this and we talk nonstop about all of the work we have left to do. Which in all honesty is peanuts compared to what we have come through!

We have not been able to set foot on or in Akupara as there was no way I wanted to be responsible for damaging the work Prodigy was doing and thereby increase the costs.

Maybe $45000 isn’t a lot for some people when it comes to paint, but it is huge as far as we are concerned. I can honestly say it is the most money we have ever spent on anything with the exception of vehicles.

Well, I hope that they finally complete the paint work once and for all so that we can get back to her and start finishing all the rest of the work. We need to get back in the water. It has been too long.

Too long of a road.

taken from: https://www.vocabulary.com/dictionary/pertinacious

pertinacious. If you won’t take no for an answer, you’re pertinacious. The same holds true if you stubbornly push on a door despite a sign that says “pull.” Pertinacious means unyielding or perversely persistent. We get pertinacious from the Latin pertinax, which combines per-, “thoroughly,” with tenax, “tenacious.”

This project has had many ups and downs. It has taken way longer than we ever anticipated. We expected to be sitting at anchor sipping drinks by now but we still have a lot of work to do before we are ready. To be completely honest there have been a couple of periods where we have simply lost interest. Akupara became more like an albatross than a dream. It has seemed like all we did for several years was work on her and write cheques, it has been downright depressing to say the least. We have had a few highs, the removal finally of those old stinking fuel tanks, even though the keel tank was the worst job an Akupara yet. When I finally installed the new electrical panel and had lights inside for the first time, when we installed the Cubic Mini Woodstove and had the first test fire! Those day were fun.

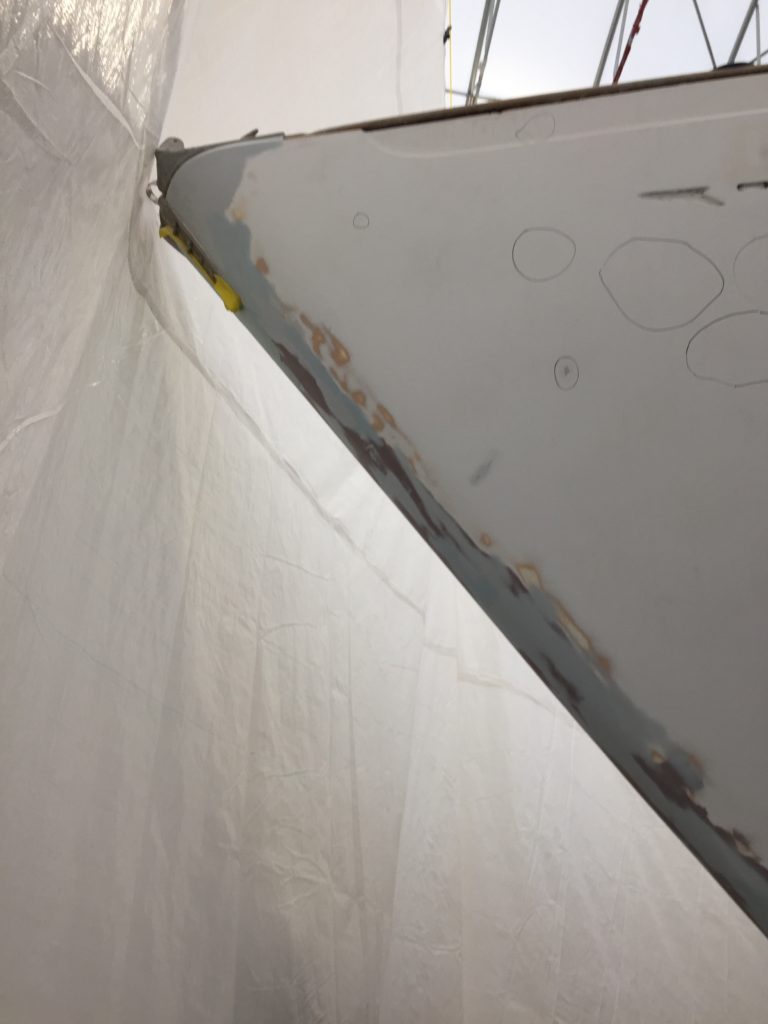

The biggest transformation and probably the most exciting has been the painting of Akupara’s hull! It took damn near 2 years but when it finally happened, my god, she is beautiful.

For the first time ever since owning Akupara, I had a small panic attack as we were removing the lifelines and a turnbuckle fell overboard dan near scratching the hull. That is a monumental step forward!!

So what has kept us going? Good question?

We have had many of these conversations over the last few days and we have now made it a priority to try to remember all of the reasons we started this project in an attempt to rekindle the fire! We have been talking about everything we enjoy, and everything we miss about sailing and generally being out on the water. With each new memory (things remembered) we can slowly feel the fire coming back.

It is of the utmost importance that now, especially now, we concentrate on all of the good things in order to make it through! If all goes well we have less than a year to finish her and get her in the water! It is just like running a marathon, you are tired, your feet hurt, your legs hurt, you are out of breath, you want to quit, but then you see that finish line and all of the negativity leaves and somehow you find the extra reserve of strength to push even harder!

Let’s hope we can find that last little bit! It’s time to get busy again!!

So are we pertinacious, or is there such a thing. Somehow I think that anyone who is described as such, consciously chooses to focus on the end results as opposed to the darkness and the hurdles that are immediately in front of them and I think they spend a lot of time forcing themselves to do so!

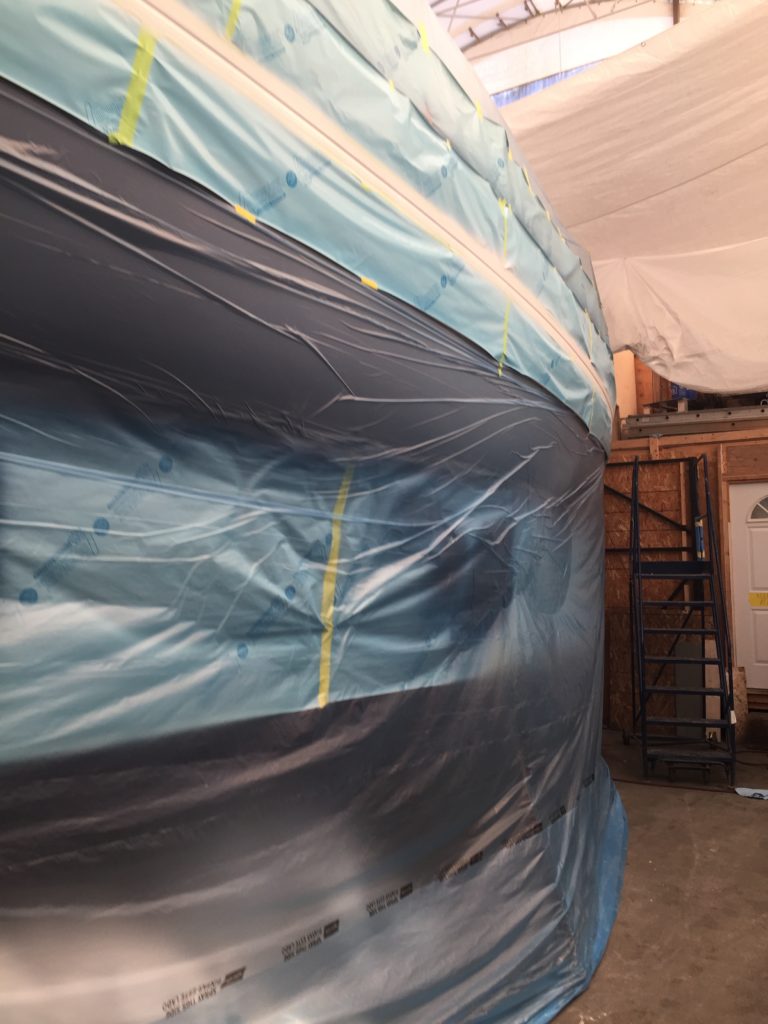

3 little stripes and you would think 3 little days. Ya no luck. Apparently each stripe takes a week….

This is the first of the Before and After photos, hopefully this turns out…

Wow I am totally blown away!!!! Akupara is a new baby!!! This is only coat 2 of 5 coats! Can’t wait to see her on Saturday!!!

Well the engine drip pan is back in finally. Glassed, sanded, and painted!!

You may have noticed that we decided NOT to replace the keel tank. I had contemplated it, also contemplated putting a holding tank down there as well. All I could think of was standing in the remnants of the old fuel tank up to my knees in stinking dirty rotten shit. Yup, empty it will stay. We still have a lot of fuel capacity with the 2 wing tanks. If and when we head offshore, if it is needed, I will pull the engine and install one but until that time, I will keep a clean bilge! ?

Well Prodigy Marine did in 5 days what it would have taken me at least 5 weekends. Sometimes it is a good call just to hire out the job!

The foredeck is back together and stronger then ever, but I do have a huge concern with it. The rest of the deck now looks like “ass”. 🙂

In a strange way it is kind of scary to see the foredeck fixed and primed. I think we have gotten so used to seeing Akupara’s outsides in a run down dilapidated state that seeing her starting to look a bit better is a shock. Ok it is only 8 square feet of foredeck that is primed, and the hull looks like a patchwork of bondo, but the progress is real. As soon as they prime the hull and it is all a smooth uniform primer colour, it is going to be a bigger shocker.

I think we need to write off next weekend to finishing the sanding and repairs on deck. To have the hull looking fantastic and the topsides looking like crap is going to be hard to take. Having it all primed would be huge!

Today’s plan is to sand and paint the engine drip pan repair I did as well as a little more paint back near the packing gland so that the entire area is nice and clean and fresh for the new engine and shaft to be installed.

That will be a major milestone as well, imagine having an engine in the engine room? Akupara has been engineless Since February 1st, 2018, almost an entire year now!

In case anyone was wondering, the template that I had been using for this website was removed. This caused the site to be down for a bit. I kept getting cryptic messages emailed to me that to be honest I ignored. Finally donned on me what the issue was so I quickly changed to this template that you see now. And no I do not really like it. I will find a better one soon. Cheers

Sometimes as I mentioned in an earlier post it is easy to get discouraged!

After I posted last time I received an email from one of the few folks out there who actually read this blog. It said:

Subject: Hang In There!!

Message:

Don’t give up! You are getting so close. I have been checking back from time to time and it is good to see you back posting again. She will look so good after a new hull job. Maybe serve as an inspiration to continue.

Hang in there!!!

This email came completely out of the blue! To be honest I had pretty much figured nobody was reading the blog especially since it had been so long since I had posted. It wasn’t a long email as you can see, but it meant a lot!

And who says the internet is just full of bad things?

Thank you for the encouragement, it is much appreciated!!

My god it’s been awhile!

To be completely honest we lost interest in this project in the fall. I struggled a bit to persevere but then got involved with some redecorating at home and that was the end of that. It jas now been 4 years since we started this and 4.5 years since I last sailed a boat.

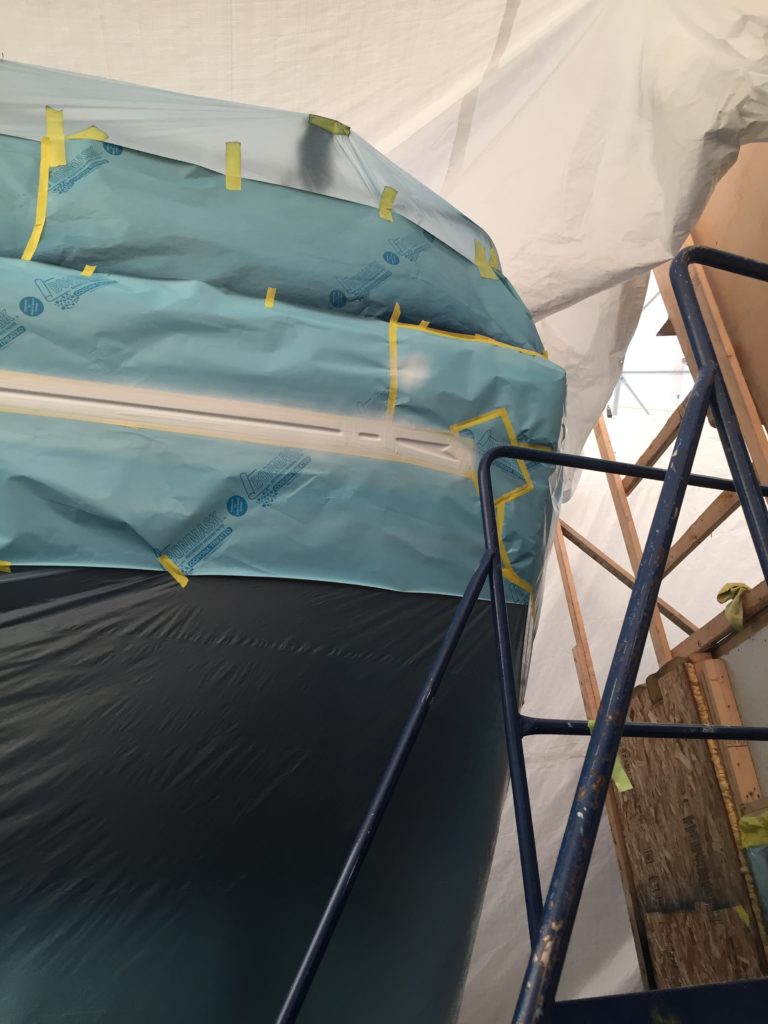

The yard messaged me last week to let me know they would be tarping the boat for primer. I was a little shocked as nothing had seemed to be happening for a very long time. It was almost like, hey dumbass, you have a boat here you know! So I took a quick trip down and snapped some pictures and of course handed over more money.

So like all good New Years resolutions, I will head back down to the yard today and see what has been happening. I need to glass in the engine drip pan so that they can get the engine install started.

I think we needed a good break from this project. Now let’s see if we can get back into it or if we should try to sell an incomplete project and try to break even.

Fingers crossed we can do this. I miss having a boat in the water and I miss sailing but it has been so long now I am not sure it is a strong enough driver anymore.

Fingers crossed!!

We have officially moved from demolition to renovation in the engine room! There is a lot of cleanup left, still need to remove a few old fuel lines, some sanding, some painting, install some insulation, have the new tanks made, install them, and then Prodigy Marine will do the new engine install, but we have officially moved out of the darkness and into the light.

Akupara looks like a bomb went off inside of her with fiberglass dust everywhere and panels from around the tanks and all kinds of stuff, but is it ever nice to be done this job! I don’t mind the new work, it is much easier of course!

And the Admiral got to see the new engine yesterday! She said it sparkles! I guess that means it’s ok! 🙂

So for anyone thinking about removing the wing tanks, it really isn’t that hard. Ok the Starboard side isn’t really that hard. Remove all of the panelling, remove about 100 screws around the top of the tank. They hold it down to the fiberglass box that it is fit into. Cut the front of the box away. Use a come-along from the cockpit, hooked into the top of the inspection plate on the tank and pull. It will slowly release itself from the foam it is bedded in and then you can pull it out through the cockpit sole. The port tank however will require a bit more work as you need to remove the exhaust, a bunch of other fittings and hoses and crap and then repeat the same process. I will let you know how it goes after I have it out.

So you have a sailboat.

You have decided that the time has come to remove the old “bag of hammers” as my cousin puts it, and put in a new “bag of hammers!”

Easy right?

Sure it is. If you whip out the chequebook and just sign away. If you want a little more input, it tends to get a little more complicated.

There are hundreds of different factors at play, I mean if you give it enough time, even colour plays a role. I mean the engine room has to look right doesn’t it?

We had narrowed it down to a couple of final decisions. Namely, Yanmar, Beta, Solé and Westerbeke. Westerbeke didn’t have anything in the size we needed so it was quickly removed from the list. so down to Yanmar, Beta and Solé. Should be easy.

Well, in the end we went with Solé. What the hell is that you ask? Well, it is a Mitsubishi engine that has been marinized in Spain. Everyone and there dog is probably jumping up and down reading this and saying OMG, you should have went with Yanmar, they are the most well known, bestest thing since slice bread. Perhaps they are, but then again perhaps it is nothing more than a really good marketing campaign! But what about Beta? They are good engines, surely it is better than a Sun, I mean Solé. Good question, maybe it is, but isn’t a Beta nothing more than a marinized Kubota? So let’s look at some stats between our 3 contestants.

Make / Model/ # Cyl / Max HP @ RPM / Total Wgt / Alternator(stnd)

Yanmar 4JH80 4 80hp @ 3200 253kgs/558lbs 125A

Beta 75 4 75hp @ 2600 414kg/910 lbs 70A

Solé Mini-74 4 63.9hp @ 2500 357kg/785.4lbs 95A

Distance between engine mounts, Yanmar 470mm/18.5inches, Beta 634mm/24.96inches, Solé 675mm/26.57. Original Ford Lehman 565./22.25

So there is no clear winner here if I do not want to have to modify the existing engine mounts. However, the Solé is 4 inches different and it is easier to expand the mounts than to have to make them narrower in my mind.

Horsepower is important for sure and the Solé is on the lighter side.

Overall weight puts the Solé in the middle.

So after all of the number crunching and tossing and turning there is one major reason we went the way we did and let’s see if you start feeling the same way.

Boat show Prices:

Yanmar came in at $20080 plus tax for a total of $22489.60

Beta came in at $16382.00 plus tax for a total of $18347.84

Solé came in at $14645 plus tax for a total of $16402.40

Sorry all you Yanmar diehards but at a difference of $6087.20, I know where my priorities are, and the Admiral keeps reminding me.

In the end I may eat my words of course, but a brand new engine looked after and cared for should last a long long time in any case regardless of the name on the side of it. Fingers crossed!

Just a side note – we did look at the Yanmar 4JH4-TE, there 75hp engine, however we ruled it out immediately when we were told it was $19681 NOT INCLUDING a transmission which would be $1-2000. And that was on sale by the way…and just to add insult to injury, not impressed when an engine goes up in price from $18500 last year to $19700 this year for no apparent reason.

No insult intended to any owners/fans or otherwise of any engine type I may have mentioned or may have not mentioned. 🙂

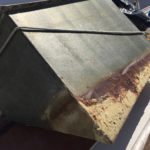

It’s out. Finally!

I have to say that was one of the worst jobs I have ever had to complete on a boat. I have never been so dirty, smelly or sore in all my boat renovation projects.

I have to say that was one of the worst jobs I have ever had to complete on a boat. I have never been so dirty, smelly or sore in all my boat renovation projects.

I am going to let the pictures tell the story and will keep my comments short.

Here I have managed to cut the rest of the glass flange that is holding the tank in place and I was able to move it a couple o finches without any issue so thankfully I knew it was free.

Here I have managed to cut the rest of the glass flange that is holding the tank in place and I was able to move it a couple o finches without any issue so thankfully I knew it was free.

This is not as quick and painless as it looks, getting to this part from initially freeing the tank was about an hour.

This is not as quick and painless as it looks, getting to this part from initially freeing the tank was about an hour.

Something strange with that light, seems to add a shiny spot on the top of my head…

Something strange with that light, seems to add a shiny spot on the top of my head… Post tank removal. Now there was about 4 inches of shit to clean out. I assume it was what was left of the foam but of course it was drenched in black crap.

Post tank removal. Now there was about 4 inches of shit to clean out. I assume it was what was left of the foam but of course it was drenched in black crap.  So what did I learn from this project?

So what did I learn from this project?

On our last boat we had a strange smell that only surfaced when we were under way. We had cleaned every square centimetre of the bilge multiple times and when at anchor or moored, the bilge smelt like flowers. Get the boat moving and it was disgusting. I have a solid belief that I know what the cause was now. There was no keel tank, however I think the encapsulated ballast had seawater fermenting around it, it is the only thing I can think of.

The keel tank is absolutely MASSIVE in size. I will be putting another tank down there, but it will not be aluminum or stainless, it will be plastic so nobody (me when I am 90) ever has to deal with a rotted out tank down in the bilge.

In hindsight we probably should have done this job right in the beginning when I was 3 years younger.

Nothing in boat repair is impossible for the do it yourselfer. We could have paid to have this done, but where is the fun in that?

Another Whitby owner who did this job commented that if he had to do it again, he could probably do it in about 3 1/2 hours. Well, I am sure I could make the same claim, or close to it now, but as is common with everything, take your initial estimate and multiply it. In this case, basically 3.5 hours meant 3.5 days for us.

I also learnt that I am getting tired of rebuilding boats.

At some point, I will put all of this together into a handy guide for any other Whitby 42 owner, in the meantime, if you have questions, please send them my way, and I will be glad to do everything in my power to talk you into paying someone else to do the job! And no I am not doing it 🙂

Okay so the tank won on the 2nd day as well. All in all I spent 7 hours working on this project today. Why so long? Let me explain.

In order to cut the tank in half so that it can be removed I needed to get rid of the last of the sludge in the bottom of the tank. This process involved standing inside the tank and using a scoop to fill 5 gallon buckets. But before that I am missing the part about cutting the top off.

Cutting the top of the tank off, well at least the portion from the old inspection plate to the back was very simple and went really quick. Sawzall and good quality Dewalt metal cutting blades did the trick in minutes. Unfortunately there is not enough room between the tank and the keel to be able to cut it in half with the sawzall. That would have made things a lot easier. once the top was off, I could get down inside and clean it out a lot better.

Unfortunately, as I mentioned yesterday, the entire tank is sitting in a puddle of water/diesel/grease and god only knows what else. The inside of the tank had a water mixture with what looks like beer fermentation foam on it. All of this had to be scooped out into 5 gallon pails, carried up on deck, down the ladder and dumped into a 40 gallon drum. And this process had to be repeated as I cut down the sides of the tank and all of the other goop poured in.

In order to cut the tank in two, I had to stand inside of it and cut it with the grinder and a good cutting blade. This process in itself isn’t really all that time consuming with the exception of all the liquid on the outside of the tank. Every time I cut the side down an inch, I had to wait until the liquid drained down to that level. This is what took so bloody long. I could not simply cut it in two as I was standing in the liquid using power tools. Not my idea of a fun day to electrocute myself removing a keel tank.

I am not sure how anyone can possibly do this job without standing inside the tank. It is a long way down to the bottom and would be impossible to cut the very bottom without standing inside, bent over and doing it with a grinder. To speed it up a little bit, I drilled a series of holes in a straight line across the bottom and finished it with the angle grinder. Of course, the grinder only fits so well into corners so I had to do a fair bit of screwing around right at the bottom.

I am not sure of the exact depth yet, but there is a fair amount of space underneath the tank itself. I thought I might be drilling into the keel, but nope.

For anyone who reads this blog and is contemplating the same job here in a nutshell are things I learned today. Bending over cutting an aluminum tank while standing in it sounds like a lot of fun I know, but it is cramped, which means you are cramped, which means you are bent over for hours trying to do this. Also, make sure the angle of your cut is in the correct direction. Mine ended up being in the wrong direction needed to remove the back half of the tank first, which meant I had to go back in and cut v notches into the tank wall.

Buy good quality blades, Dewalt worked great for me.

Whatever this mess of liquid is stinks up to high hell and even after a 30 minute super hot shower with lots of soap, you can still smell it on yourself.

The success for the day is that the tank is officially in 2 pieces now and the back chunk should come out now.

This is definitely one of those jobs that make you ask yourself why. Why rebuild boats? I am so sore this morning it is nuts (I work in software, not physically demanding jobs) Sure we could pay someone to do this but it would be expensive and it would take all the “fun” away.

I am going to try to finish this job today, but I have to return to work tomorrow and I would like a little bit of relaxation this weekend so I am not sure how far I will get, and of course I feel like I was hit by a train.

Did I mention I am sore?

Total time to actually cut the tank, including a 1.5″ x 1.5″ hole to attach the winch to get it out – 2 hours