I knew the chainplates leaked. I also knew they leaked fairly badly. What I did not know was that the area of deck where the chainplates make their appearance is cored. I also did not know that the original way these holes were created did not include sealing the coring. Well, it did not take long to find all of this out.

I decided yesterday to start pulling the chainplates in the aft cabin before we get too far ahead of ourselves and to fix the rot in the bulkheads. Fixing the rot in the bulkhead is not going to be that big of a job, but nevertheless I have been putting it off, however the decision was made to begin the fix which necessitates removal of the chainplates. First thing I noticed right off the bat was that the bolts holding the chainplate in place, were not even tight. Hmmmm. Second thing I noticed was that there was several layers of what I can only assume was 3m4200 or something very similar. Of course the 5 spare tubes we found in the cleanout also indicate a preference to this goop. Anyway, after cleaning out as much of the goop as possible, and removing all of the snug bolts, I pried from below decks and Andrea pulled from on deck and sure enough they popped out. This of course presented me the opportunity to discover the facts above. It became quickly obvious that an immediate repair was needed, and it became quickly obvious that I can be almost guaranteed that every other chainplate will require the same repair.

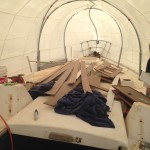

My repair process involved cutting out approximately 5″ square of the top skin around the existing holes. As soon as I began cutting the top skin it was painfully obvious that there was water damage. There is a smell that rotting wood has it and it was in the air. In the pictures you can see black core, which is already rotten and the somewhat light brown colour is wet. After removing this piece of top skin I scraped all of the remnants of coring out of the hole, ground it down with 60 grit sandpaper and cut a plug out of 3/4″ marine ply to fill in the section of now missing core. The original thickness of the coring here is closer to 1/2″ which means that my plug is almost flush with the top skin. This is by design so don’t panic. I placed a small piece of duct tape over the original holes on the bottom skin to prevent epoxy from running down inside of the boat, filled the areas that I had dug out underneath the remaining top skin, poured a bed of thickened epoxy into the hole, and placed the new coring in, completely covering it with epoxy. So now I have a solid area about 6″ square around the old holes.

The next step will be to grind the area concave including farther out than the 5″ piece I cut out in the top skin, drill a hole about 3″ in diameter where the chainplates will be through the plywood coring down to the bottom skin, fill the hole completely with thickened epoxy and add a layup of several layers of glass to the entire area until it is slightly proud of the surrounding deck. At this point I am going to take it one step farther. I am going to raise the 3″ diameter hole that has been filled with thickened epoxy, up past deck level by approximately a 1/2″. This will help eliminate any water intrusion as any water that finds its way on deck will run around the raised area. The purpose of the 3″ solid epoxy hole is that any water that might find its way down the chainplates will not be able to penetrate the coring as they will be surrounded by solid glass.

I only have to repeat this 9 more times for the rest of the chainplates and all will be good in the world again. But I will never have to repair these areas again.

A word of advice to all of the Whitby owners out there. Pull your chainplates, and make sure the coring around them is not wet. If it is not, at least seal the holes with epoxy and make sure it never does get wet.

While I was messing around with pulling chainplates and repairing core, I also replaced all of the temporary screws that were holding in any of the interior panels that we have put back. As I mentioned before in previous posts, every screw that is used on Akupara from here on in will be a Robertson screw. For those of you who do not know what a Robertson screw is, it is a square slot as opposed to just a slot, or a Philips which is a star shape, or any other type of screw for that matter. I have always found Robertson screws afford the best chance of NOT stripping them thereby making them removable for all time.

Andrea and Paige began the process of painting all of the bilges and lockers with Bilgekote paint. Andrea wanted white as opposed to the traditional grey, and after seeing the newly painted areas gleaming with fresh white paint, I think she made the right choice. Bilgekote is easy to apply and gives good coverage. It is also very hard once cured and is supposed to be very abrasion resistant. We actually started asking ourselves why we shouldn’t use white Bilgekote to paint the sole in Akupara as well. Abrasion resistant, tough, white, what more can we ask for? I will need to do a little research to see if there is any reason why we should not, but if I do not find anything, I think we have a solution to the 40 year old yellowish floors.